PROCESSES

This is what we are known for

Functional surfaces give you the security of reliable processes and long service lives. Pallas is a proven partner for optimally selected coating materials and processes..

ELECTROPLATING

A small layer, big impact - electroplating

...are the most original surface finishing techniques and at the same time the root of Pallas. Layers in the µm range are deposited on metal in electrolytic baths.

In the course of development, we have established three processes that solve the technical requirements of our customers in different ways.

Electroplating protects the base material steel from corrosion in a simple way. We plate the smallest mass-produced parts as well as large components.

Hard chrome and chemical nickel are complex, functional coating processes. They fulfil several requirements at the same time: Dimensional accuracy, corrosion and wear protection. Chrome also offers excellent sliding properties. Useful subsequent processing steps - e.g. tempering or grinding - round off our portfolio.

- A wide variety of processes under one roof

- Good corrosion and wear protection with thin layers

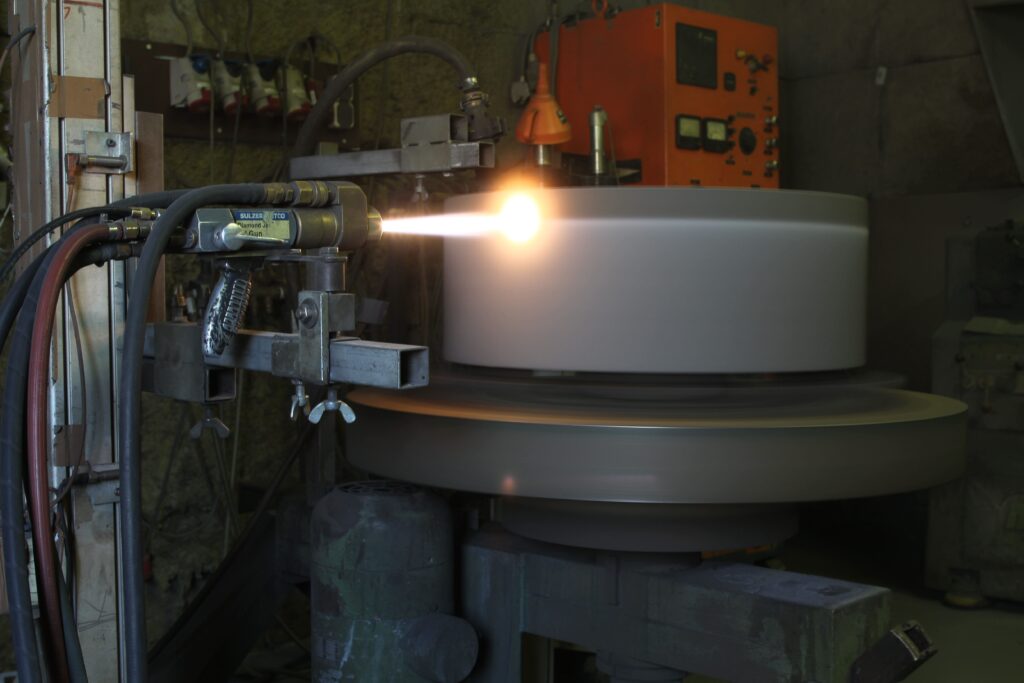

THERMAL COATINGS

Layers for all occasions

In addition to electroplating processes, Pallas has been using almost all thermal coating processes since the 1970s: Plasma, HVOF (high velocity oxy-fuel spraying), arc spraying as well as wire and powder flame spraying. High-quality ceramic and metallic materials are used. Appropriate pre- and post-processing of the components is a matter of course.

LASER / iClad

Technology of the future

Research and development (R&D) and laser processing are closely linked. Applications and coating systems using lasers were already being developed at Pallas at the beginning of the 1990s.

Two main methods are used: The Laser hardening selectively hardens the near-surface areas of a component by structural transformation. Through Laser build-up welding new materials can be applied, resulting in a welded metallurgical bond with the base material.

ICLAD

iClad® / Compact head for big tasks

iClad® is a proprietary development that we take pride in: a specialized laser optic for processing internal surfaces starting from just 30 mm in diameter

The result is a compact laser processing head for internal coating of diameters from 30 mm and a coating depth of up to 1000 mm, with which we cover the entire spectrum of surface processing (hardening, alloying, coating) in order to process the internal surfaces of defective components or to optimise existing components. All necessary assemblies for beam guidance and shaping as well as for the supply of process media are housed in a compact casing.

The modular, easy-to-maintain design of iClad® is tailored to customer needs. Parameters aligned with specific processes ensure durable and stable process flows. Internal optic protection and continuous gas flushing of the beam path prevent contamination, ensuring optic functionality even under challenging conditions.

iClad® can be coupled with various laser sources. For process monitoring or adjustment, a camera connection is available.

As users and developers of the optic, we support our customers with employee training, hands-on application assistance, and help determine process parameters. With our extensive experience, we are your sustainable partner beyond the purchase.

- A wide variety of processes under one roof

- Good corrosion and wear protection with thin layers

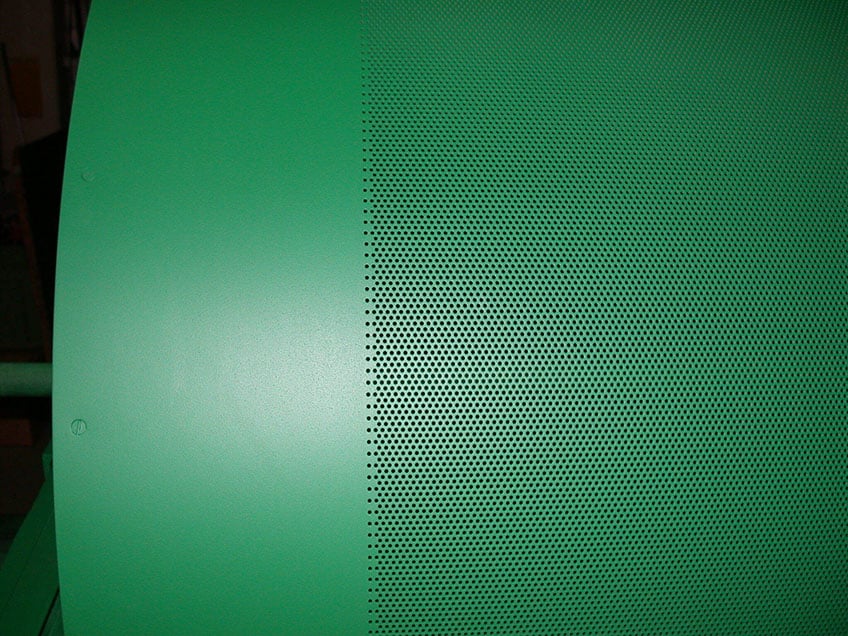

PTFE / POWDER COATINGS

Everything in flux

When it comes to functional surfaces, we are also talking about organic coating systems.

Pallas offers functional non-stick and anti-friction coatings as well as decorative powder coatings. The wide variety of coating materials enables us to offer solutions to various industries (food industry, medical technology, mechanical engineering and chemical industry).

In principle, all heat-resistant materials can be coated.

Processes

Hard chrome

Electroless nickel

Laser coating

Laser alloying

Laser hardening

HVOF/hard metal

Plasma/Ceramic

Field of application (examples)

Hydraulic pistons, bearing seats, rollers

General mechanical engineering

Worms, shafts, bushes

Tools (punching, bending)

Cutting, bending tools, nozzles

Pump parts, slide valves, rollers, hydraulic pistons

Rollers, sealing surfaces, electrical and thermal insulation, high-temperature applications

Verfahren & Einsatzgebiete

Hard chrome

Hydraulic pistons, bearing seats, rollers

chemical nickel

General mechanical engineering

Laser coating

Worms, shafts, bushes

Laser alloying

Tools (punching, bending)

Laser hardening

Cutting, bending tools, nozzles

HVOF/hard metal

Pump parts, slide valves, rollers, hydraulic pistons

Plasma/Ceramic

General masc. rollers, sealing surfaces, electrical and thermal insulation, high-temperature applications mechanical engineering

COMBINATION LAYERS

Everything from a single source

Pallas is capable to combine coatings from various processes, creating coating systems with completely new properties. The combination of different coatings on the same component allows for the application of materials suitable for specific areas with varying demands. In essence, our customers receive everything from a single source - with the associated advantages in terms of timing and pricing..

- A wide variety of processes under one roof

- Good corrosion and wear protection with thin layers