- Pallas Oberflächentechnik GmbH & Co. KG

Individual surface technology from a single source

Customised surface technology from a single source

Functional surfaces provide you with the security of reliable processes and long service lives. Pallas is your partner for high-quality surfaces. Cross-process solutions and optimally selected coating materials qualify us as leading specialists for demanding tasks.

Your requirements - our solutions

Service

Due to our wide range of technologies, we can always choose the perfect, most efficient and cost-effective process - feel free to contact us!

Insulation

Wear

With preventive protective coatings, we extend the service life of your components, reduce downtimes and thus increase the operating life of your systems.

Repair

Time is money, especially when critical components fail. As an alternative to costly new production, we provide fast and effective help: We repair faulty components using state-of-the-art technologies - often within a few days.

Corrosion

Targeted protection against corrosion on your components is a prerequisite for the economic efficiency and safety of your production processes. We protect vulnerable components with suitable coatings. With individually tailored solutions, we provide you with the security of long service lives.

iClad®

With our iClad® processing optics for laser build-up welding of internal contours from Ø 30 mm upwards, we are also demonstrating in our youngest division our innovative competence as a system provider.

Competences & processes

Electroplating - added value through metal coating

Electroplating provides your components with specific properties through µm-precise metal coatings

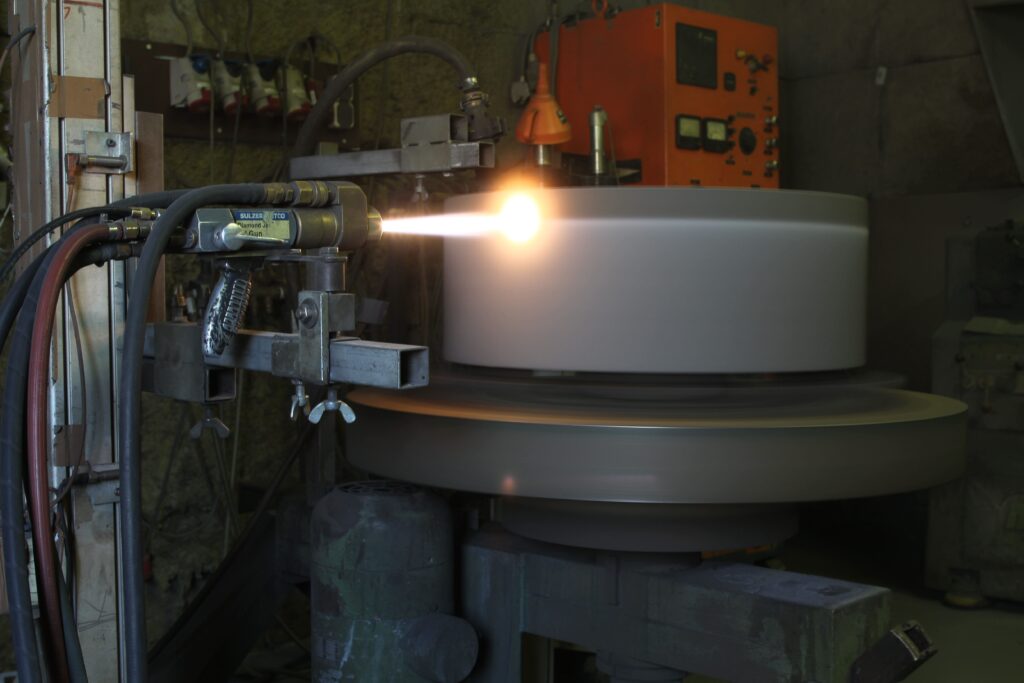

Thermal coating - for all cases

Thermal coating is the process of choice for a wide range of applications, both technically and economically.

PTFE coatings - everything in flow

PTFE coatings ensure smooth processes due to their non-stick effect.

Laser - technology of the future

Build-up welding of the highest precision: spot-on, low distortion, heavy-duty.

Surfaces with tradition

Innovative surface processing is a longstanding tradition for us - spanning over 80 years. To this day, we strive to transform good ideas into functional surfaces, ensuring reliability and quality that you can trust tomorrow and beyond.

1940s

years -

Foundation of Metallveredelung Fleuster KG

1965 -

Foundation of Pallas GmbH

1969 -

Foundation of Eloxalwerk Fleuster KG

1976 -

Introduction Wire Flame Spraying

1979 -

Introduction plasma process

1980 -

Introduction of high-speed flame spraying

1989 -

Environmental Award of the State of NRW for the water treatment plant & commissioning 2.5 kW CO2 laser for coating, hardening, alloying

1992 -

Introduction of PTFE processes

1993 -

Introduction plasma powder build-up welding

1996 -

Change of name to Pallas GmbH & Co. KG

2000 -

Takeover of the operative business by the 3rd generation

2004 -

Construction and approval of the new water treatment plant

2005 -

Takeover of the management by the 3rd generation

2008 -

Commissioning 2 kW Nd:Yag laser

2009 -

Market launch iClad®

2014 -

Commissioning 6 kW diode laser with robot handling

2018 -

Commissioning 3 kW diode laser as mobile system

2020 -

Commissioning cylindrical grinding machine Ø 800×3800 mm

2022 -

Expansion of the production areas

OUR SOCIAL MEDIA

Get more insights on our social networks

On Instagram in particular, we regularly give you new insights behind the scenes and inform you about important events and news.

JOIN THE TEAM

Bring in your experience and drive the industry forward.

Looking for a new challenge? Then take a look at our vacancies and discover your new position within the Pallas team.